Design Constraints Hindering Construction & Building Performance

With stricter U-value and thermal performance targets now required for most buildings, we are constantly set the challenge of finding and using products which can assist in overcoming the design constraints involved in achieving these targets and then balance them in cost vs benefit scenarios.

Written by Neil Kirwan and Hitesh Pattni, Specification Managers in SFS Group Fastening Technology Ltd.

So what are the two main challenges specifiers and engineers face when considering Thermal Performance?

Substitution of PIR and Phenolic insulation materials.

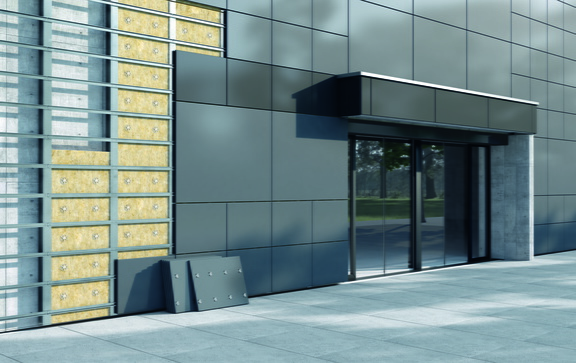

In the light of Grenfell and the move away from away PIR and phenolic based insulation even on buildings below 18m we are seeing the increased requirement and specification of Mineral Wool equivalents. This creates the first issue in terms of a Rainscreen application as Mineral wool does not have the same levels of insulating performance at similar thicknesses as for example PIR.

Increase cladding zones, footprint and cost.

The traditional way to counteract this is to increase the cladding zones and building footprint (often considerably) by increasing the thickness of insulation and in turn larger helping hand brackets which increase not only project costs but potentially lead to proposed boundary or internal space restrictions. In terms of bigger picture costs, there are ways we can try to address these challenges and there may be some trade off needed.

Architects and designers need to be provided with a range of options and solutions to overcome these challenges.

To meet this need SFS recently launched its Thermal Solutions range to help bridge any ‘performance gap’ and balance budget constraints with thermal performance matching the specific requirements of the customer & client.

The right tools

Thermal solutions range includes Aluminium & Stainless Steel brackets and thermal pad options to further increase performance, essentially it is a system lead approach with good…better…best performance options which can then be weighed in an overall cost vs benefit analysis. This approach enables the Architect and Designer to identify if a potential reduction in insulation thickness, cladding zones and bracket sizes, whilst maintaining thermal performance; would better suit the project overall.

Early engagement

Equally early engagement within the project is crucial so that the Architect and Designer can see the potential options available to them. Even in the early stages of a projects design manufacturers like us can work with and assist specifiers with guidance and solutions. SFS Project Builder software can simplify the specification process for architects and designers with tools to assist and guide you from the early stages of design.

English (Canada)

English (Canada)

čeština (Česká republika)

čeština (Česká republika)

magyar (Magyarország)

magyar (Magyarország)

Deutsch (Deutschland)

Deutsch (Deutschland)

eesti (Eesti)

eesti (Eesti)

español (España)

español (España)

português (Portugal)

português (Portugal)

English

English

suomi (Suomi)

suomi (Suomi)

français (France)

français (France)

italiano (Italia)

italiano (Italia)

Nederlands (Nederland)

Nederlands (Nederland)

norsk, bokmål (Norge)

norsk, bokmål (Norge)

polski (Polska)

polski (Polska)

svenska (Sverige)

svenska (Sverige)

Türkçe (Türkiye)

Türkçe (Türkiye)