isoweld®

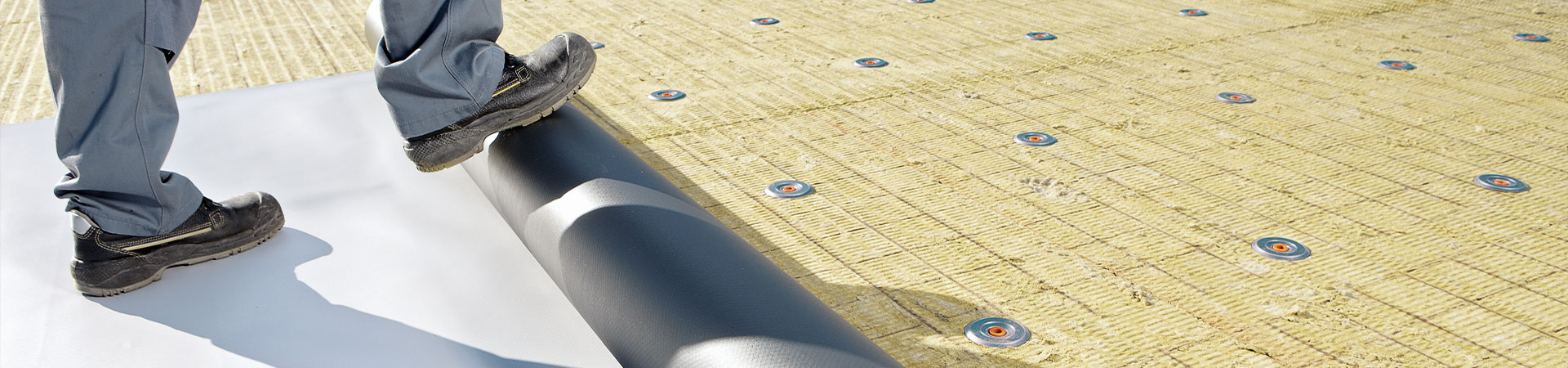

Innovative fastening system using induction technology for a non-penetrating field fastening solution

The isoweld fastening system uses induction technology to weld single ply membrane to dedicated stress plates, securing it to the roof surface. The innovative system increases efficiency, ensures security, and saves on cost.

Fast welding, speedy installation

Welding time is just 3 seconds per plate maximising productivity. Covering of the roof is fully independent of the fastening process, further speeding up installation.

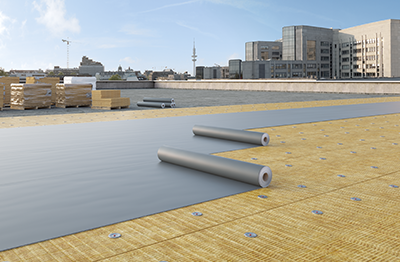

Cost savings for a competitive advantage

This field fix fastening system uses up to 50% fewer fasteners, and combined with the fact that only one membrane width is required for the entire roof, this typically results in 20% less seam welding. Additionally, because the fasteners are not located within the membrane lap joints, the system offers up to 4% increased membrane coverage. Projects undertaken have shown that installers can save up to 20% of the total installed system cost.

Security features for quality weld

Secure weld quality every time thanks to security features like the search and control function which indicates when the plate is correctly underneath the inductor.

20 million m2 of single ply membrane has been successfully installed using the isoweld system since launch.

20 million m2 of single ply membrane has been successfully installed using the isoweld system since launch.

Easy handling saves time

The isoweld 3000 machine is easy to use and set up. Calibration is fast and simple, saving time and providing security and peace of mind to the installer. SFS provides site training and a full contractor support package.Versatility to suit your project

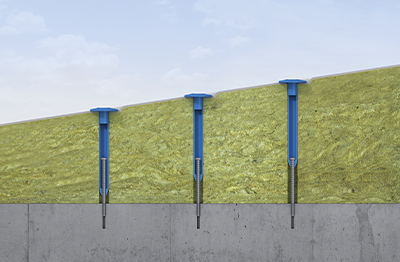

isoweld can be used on different substrates with or without thermally broken sleeves and is suitable for use with:- Approved PVC, TPO & EPDM membranes

- PIR insulation, tissue or foil faced

- EPS application with FI-Pad

- Stone wool insulation

- Steel, concrete, timber or critical roof decks

English (Canada)

English (Canada)

čeština (Česká republika)

čeština (Česká republika)

magyar (Magyarország)

magyar (Magyarország)

Deutsch (Deutschland)

Deutsch (Deutschland)

eesti (Eesti)

eesti (Eesti)

español (España)

español (España)

português (Portugal)

português (Portugal)

English

English

suomi (Suomi)

suomi (Suomi)

français (France)

français (France)

italiano (Italia)

italiano (Italia)

Nederlands (Nederland)

Nederlands (Nederland)

norsk, bokmål (Norge)

norsk, bokmål (Norge)

polski (Polska)

polski (Polska)

svenska (Sverige)

svenska (Sverige)

Türkçe (Türkiye)

Türkçe (Türkiye)