NV9 Rainscreen Subframe System

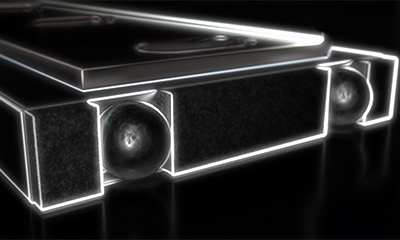

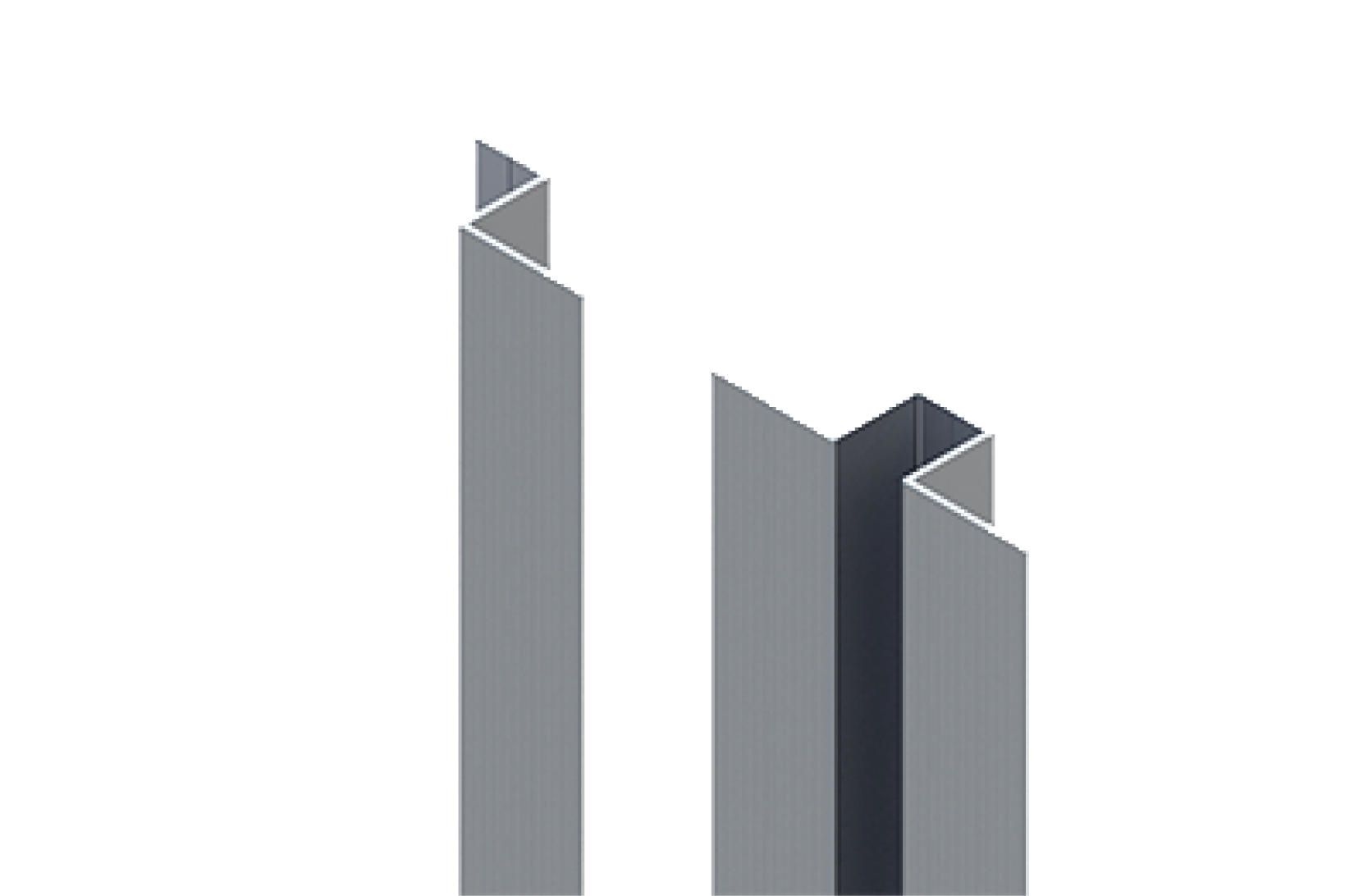

The NV9 is the simplistic NVELOPE® support system comprised of Omega and Zed profiles

Suitable for rainscreens with a shallow cladding zone either 25mm, or 40mm, this simplistic system does not allow for level and adjustment between the substrate and the front of the façade.

Features

The NV9 system is only suitable for face fixed or adhesive secret fix panels. Zed profiles are used at the corner junctions of the façade and Omega profiles are used on panel joints. The profiles are screwed straight back to the substrate using primary fixings.Material

The selection of materials to use in the construction of a subframe system within a rainscreen façade is of paramount importance. Material choice can also affect the thermal performance of the overall rainscreen in addition to engineering assurance.

Aluminium

- Aluminium subframe systems for rainscreen are designed in accordance with BS EN 1090-3:2008 and / or Euro code 9 – Parts 1-4

- Aluminum is the second most widely used metal after iron and as such has a robust and well defined UK and international supply chain

- Its low weight and high strength ratio and simplicity of fabrication either on site or within a manufacturing setting ensures it is an ideal material with which to create high performance rainscreen subframe systems for cladding applications.

- Aluminium is inherently corrosion resistant however this can be complemented and further improved by additional treatment including anodization whilst still maintaining a Euroclass A1 fire rating.

- NVELOPE systems only use the superior 6005 T6 alloy which provides superior strength and performance over and above other commonly used aluminum.

Stainless Steel

- Stainless steel subframe bracket systems for rainscreen are designed in accordance with BS EN 1090-3:2008 and / or Euro code 3 – Table 5.1

- NVELOPE stainless steel brackets are only manufactured from a superior 316 grade of alloy to provide an outstanding level of resistance to localised corrosion such as maritime and polluted areas.

Sustainability

Sustainability is a key factor in the design of any building. Identifying the right material from a sustainable manufacturer with a credible supply chain and responsible sourcing is crucial. At SFS:- The aluminium we manufacture from is 100% recyclable

- The alloy we use is made from 100% re-melted material

- 6063 alloy as used by many other sub frame manufacturers' can only utilise 40% recycled scap due to global shortages.

- CO2 production as a consequence of extrusion alone estimated at 0.35 - 0.5Kg per Kg currently.

English (Canada)

English (Canada)

čeština (Česká republika)

čeština (Česká republika)

magyar (Magyarország)

magyar (Magyarország)

Deutsch (Deutschland)

Deutsch (Deutschland)

eesti (Eesti)

eesti (Eesti)

español (España)

español (España)

português (Portugal)

português (Portugal)

English

English

suomi (Suomi)

suomi (Suomi)

français (France)

français (France)

italiano (Italia)

italiano (Italia)

Nederlands (Nederland)

Nederlands (Nederland)

norsk, bokmål (Norge)

norsk, bokmål (Norge)

polski (Polska)

polski (Polska)

svenska (Sverige)

svenska (Sverige)

Türkçe (Türkiye)

Türkçe (Türkiye)